德国新型纯电动汽车电机曝光,不用稀土,磁铁,传动效率96%以上(En)

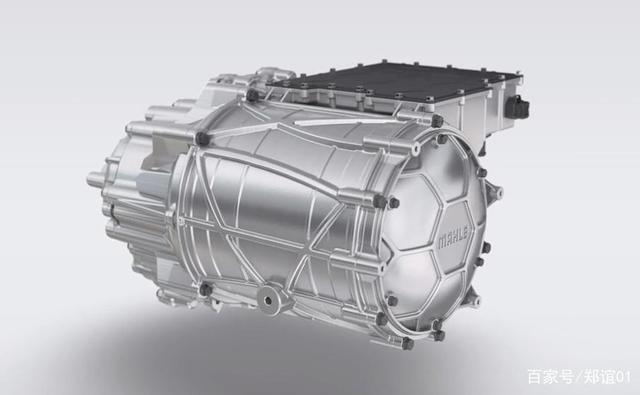

德国汽车零部件公司马勒,开发出高效率的EV用电动机,预计不会出现稀土供需压力。

与内燃机不一样,电动机的基本结构和工作原理出奇地简单,我想很多人小时候都玩儿过“四驱车”里面就有一个电动马达。

电动机工作原理是磁场对电流受力的作用,使电动机转动。电动机是把电能转换成机械能的一种设备,它是利用通电线圈产生旋转磁场并作用于转子形成磁电动力旋转扭矩。电动机使用方便、运行可靠、价格低廉、结构牢固。

所以我们生活中很多东西能够旋转的东西,比如说电吹风,吸尘器等等,都有电动机的身影。

而纯电动汽车里的电动机,相对来说就大得多,也复杂得多,但是基本原理是一样的。

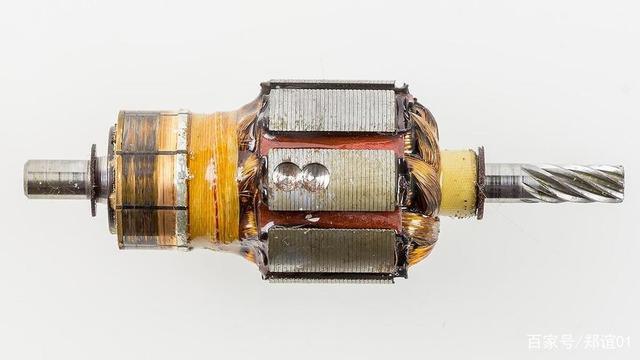

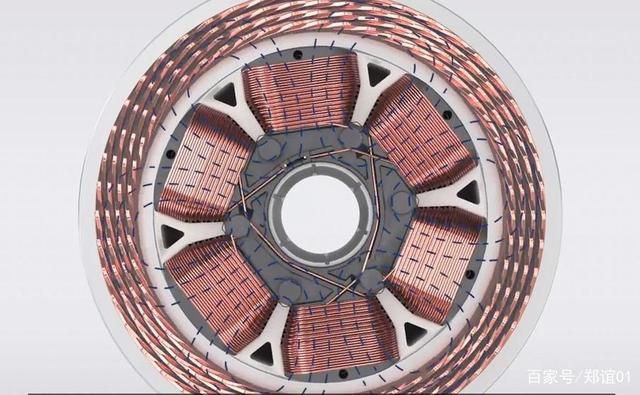

电动机中所需要的传递力的材料,从电池中导电的材料就是电机内部的铜线圈。而形成磁场的材料正是磁铁。这也是构成电动机的两个最基本材料。

过去,电动机中使用的磁铁主要是铁制的永磁体,但问题是磁场的强度是有限的。因此,如果将电机的尺寸缩小到今天插入智能手机的程度,则无法获得所需的磁力。

然而,在 1980 年代,出现了一种新的永磁体,叫做“钕磁铁”。钕磁铁的强度大约是传统磁铁的两倍。因此,它被用于比智能手机更小、功能更强大的耳机和头戴式耳机中。除此之外,我们日常生活中不难发现“钕磁铁”。现在,我们生活中一些扬声器,电磁炉,手机中,都包含有“钕磁铁”。

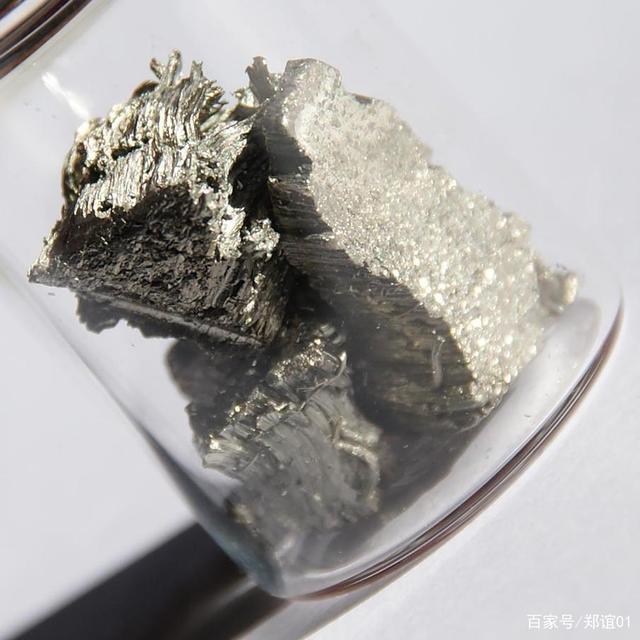

而今天电动汽车能够如此迅速地启动的原因是由于“钕磁铁”可以显着改善电机的尺寸或输出。然而,在进入21世纪之后,又出现了一个新问题,这是因为钕磁铁中使用了稀土。而稀土资源大部分都在中国,根据统计,世界上大约97%的稀土磁铁原材料是由中国供应的,目前这种资源已经被严格的限制出口。

在开发出钕磁铁之后,科学家们试图开发出更小、更强大、甚至更便宜的磁铁,但都失败了。由于中国控制了各种稀有金属和稀土的供应,也有分析认为电动汽车的价格不会像预期的那样下降。

然而,最近,德国汽车技术和零部件开发公司“马勒”成功开发出一种完全不含稀土元素的新型电机。开发的电机根本不包含磁铁。

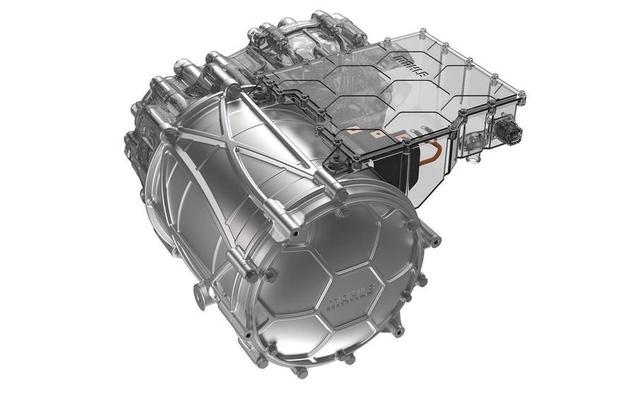

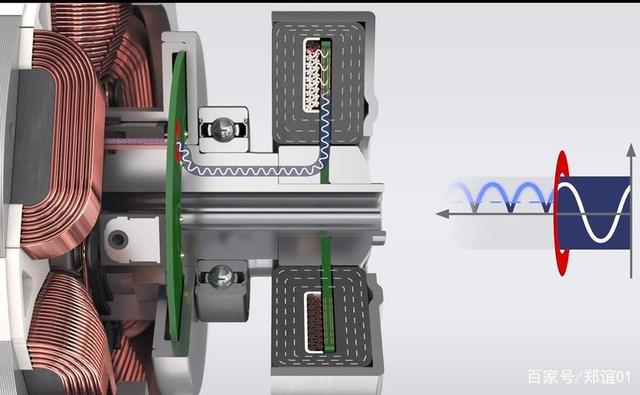

这种电机方法就是“感应电机”,它通过使电流流过定子而不是电流可以流过的磁铁来产生磁场。此时转子受磁场作用时,会感应出电动势能,两者相互作用产生旋转力。

简单地说,如果通过用永磁铁包裹电机来永久产生磁场,那么这种方法就是用电磁铁代替永磁体。这种方法有很多优点,操作原理简单,非常耐用。最重要的是,发热效率几乎没有降低,钕磁铁的缺点之一是在产生高热量时其性能会下降。

但是它也有缺点,由于电流继续在定子和转子之间流动,因此发热很严重。当然,可以充分利用收集产生的热量并将其用作车内加热器。除此之外,还有几个缺点。但马勒公司宣布他成功开发了一种无磁电机,弥补了感应电机的缺点。

马勒在其新开发的无磁电机中拥有两大优势。一是不受稀土供需不稳定性影响。如上所述,目前用于永磁铁的稀土金属大部分由中国供应,但无磁电机则不受稀土供应压力的影响。另外,因为不使用稀土材料,所以可以以较低的价格供应。

另一个是它显示出非常好的效率,电动汽车中常用的电机的效率约为 70-95%。换句话说,如果您提供 100% 的电源,则最多可以提供 95% 的输出。但是,在这个过程中,由于铁损等损耗因素,输出损耗是不可避免的。

然而,据说在大多数情况下,马勒的效率超过 95%,在某些情况下高达 96%。虽然具体数字还没有公布,但预计续航里程相比前代车型会略有增加。

最后,马勒解释说,开发的无磁电机不仅可以用于普通乘用电动车,还可以通过放大用于商用车。马勒表示已开始量产研究,他坚信,一旦新电机的开发完成,他将能够提供更稳定、成本更低、效率更高的电机。

如果这项技术完成,也许马勒的先进电机技术可以成为更好的电动汽车技术的新起点。

German auto parts company Mahle has developed high-efficiency electric motors for EVs, and it is not expected that there will be supply and demand pressures for rare earths.

Unlike the internal combustion engine, the basic structure and working principle of the electric motor are surprisingly simple. I think many people have played with an electric motor in a four-wheel drive as a child.

The working principle of the motor is that the force of the magnetic field on the current causes the motor to rotate. The electric motor is a device that converts electrical energy into mechanical energy. It uses an energized coil to generate a rotating magnetic field and acts on the rotor to form a magnetoelectric rotational torque. The motor is easy to use, reliable in operation, low in price and firm in structure.

Therefore, many things in our life that can rotate, such as hair dryers, vacuum cleaners, etc., have electric motors.

The electric motor in a pure electric vehicle is relatively much larger and more complicated, but the basic principle is the same.

The material required in the motor to transmit force, and the material that conducts electricity from the battery is the copper coil inside the motor. The material that forms the magnetic field is the magnet. These are also the two most basic materials that make up the motor.

In the past, the magnets used in electric motors were mainly iron permanent magnets, but the problem was that the strength of the magnetic field was limited. So if you downsize the motor to the point where it plugs into a smartphone today, you wont get the magnetic force you need.

However, in the 1980s, a new type of permanent magnet, called a neodymium magnet, appeared. Neodymium magnets are about twice as strong as conventional magnets. As a result, it is used in earphones and headsets that are smaller and more powerful than smartphones. In addition, it is not difficult to find neodymium magnets in our daily life. Now, some speakers, induction cookers, and mobile phones in our lives contain neodymium magnets.

And the reason EVs can start so quickly today is because neodymium magnets can significantly improve the size or output of the motor. However, after entering the 21st century, a new problem has arisen, which is due to the use of rare earths in neodymium magnets. Most of the rare earth resources are in China. According to statistics, about 97% of the worlds rare earth magnet raw materials are supplied by China. At present, the export of such resources has been strictly restricted.

After developing neodymium magnets, scientists have tried and failed to develop smaller, stronger, and even cheaper magnets. As China controls the supply of various rare metals and rare earths, there are also analysts who believe that the price of electric vehicles will not drop as expected.

Recently, however, the German automotive technology and components development company MAHLE has successfully developed a new type of electric motor that is completely free of rare earth elements. The developed motor contains no magnets at all.

This motor method is called an induction motor, and it creates a magnetic field by passing current through the stator instead of the magnets through which the current can flow. At this time, when the rotor is affected by the magnetic field, electromotive force energy will be induced, and the interaction between the two will generate rotational force.

Simply put, if the magnetic field is permanently generated by wrapping the motor with permanent magnets, then the method is to replace the permanent magnets with electromagnets. This method has many advantages, the principle of operation is simple, and it is very durable. Most importantly, there is little reduction in heat generation efficiency, one of the disadvantages of neodymium magnets is that their performance decreases when high heat is generated.

But it also has the disadvantage that the heating is severe as the current continues to flow between the stator and rotor. Of course, the heat generated can be fully harnessed and used as an interior heater. Apart from that, there are several disadvantages. But Mahler announced that he had successfully developed a magnetless motor that compensated for the shortcomings of induction motors.

MAHLE has two major advantages in its newly developed magnetless motors. First, it is not affected by the instability of rare earth supply and demand. As mentioned above, most of the rare earth metals currently used in permanent magnets are supplied by China, but non-magnetic motors are not affected by rare earth supply pressures. In addition, since rare earth materials are not used, it can be supplied at a lower price.

Another is that it shows very good efficiency, the efficiency of motors commonly used in electric vehicles is around 70-95%. In other words, if you supply 100% of the power, you can supply up to 95% of the output. However, in this process, output loss is inevitable due to loss factors such as iron loss.

However, MAHLE is said to be more than 95% efficient in most cases, and as high as 96% in some cases. While exact numbers havent been announced, expect a slight increase in range over the previous model.

Finally, Mahler explained that the developed non-magnetic motor can be used not only in ordinary passenger electric vehicles, but also in commercial vehicles by scaling up. Mahler said studies on mass production have begun, and he is confident that once the development of the new motor is complete, he will be able to provide a more stable, lower cost and more efficient motor.

If this technology is completed, perhaps MAHLEs advanced motor technology could be a new starting point for better electric vehicle technology.